Permitting

Permitting efforts and baseline data collection at the Copper Flat Mine began in June 2010 and the Company has been focused on permitting the mine for the past several years. In the United States, federal and state laws ensure mine operations are conducted responsibly. The Company is committed to achieving state and federal standards for data collection, regulatory compliance, public involvement and environmental protection. Our stakeholders (the public, community leaders and government officials) are invited at multiple stages to participate in the permitting and evaluation processes of the mine.

The mine property is located on a combination of federal, state and private lands. In order to approve the use of the federal lands and in compliance with the National Environmental Policy Act (NEPA), an Environmental Impact Statement (EIS) is required. The Bureau of Land Management (BLM) is the lead federal agency for the NEPA process in coordination with a number of state agencies that regulate mining and protect natural resources.

Several significant environmental studies have been completed on the proposed mine, including:

- Development of the environmental baseline of the mine permit and surrounding areas

- Geochemical characterization of the site’s potential for acid rock drainage and predictive geochemical modeling for the tailing storage facility, waste rock disposal facility and the future pit lake

- Completion of an aquifer pumping test to measure response at other supply wells in area to support development of a groundwater pumping and response model for the Copper Flat water supply wells

- Completion of the Federal Environmental Impact Statement and State Environmental Evaluation

NMCC has acquired several required permits for the Copper Flat Mine, including the BLM Record of Decision on the Final Environmental Impact Statement, U.S. Army Corps of Engineer authorization under the US Clean Water Act, a State Air Quality Permit and a State Groundwater Discharge Permit. Work to obtain a mining permit from the NM Mines and Minerals Division (MMD) is ongoing. The Copper Flat Mine is being permitted as a new mine under Part 6 of the New Mexico Mining Regulations. The NMCC permit application package, which includes construction, operation, reclamation and closure plans, has been submitted to MMD and was determined to be approvable by the Agency in a July 13, 2018 letter to NMCC.

Environment / Sustainability

Water Savings

Water is needed for ore processing, dust control, and other important activities. Water is a limited resource in New Mexico and the Copper Flat Mine will employ best management practices (BMPs) to conserve this valuable resource. These BMPs include monitoring water use, providing for water conservation and water recycling.

70% of the water used for the Copper Flat Mine will be recycled The single largest source of water for reuse will be process water reclaimed from mine tailings. Other sources are:

- Capturing and using storm water runoff from mine facilities

- Using water pumped from the pit to keep it dry during mining

- Dewatering the mineral concentrates produced by ore processing

- Treating and recycling sanitary system and gray water produced on site.

Water conservation will be achieved by implementing operation BMPs such as:

- Reducing evaporation loses through management of water storage areas

- Install water flow tracking and control devices for real time monitoring of water use

- Specify and use water efficient fixtures

- Re-vegetate and/or treat surface areas to reduce the need for dust control water

Elephant Butte Lake — Judd Bradley

Elephant Butte Lake — Judd Bradley

Environmental Monitoring

Environmental monitoring on site will assure that Copper Flat operations and facilities are running according to design and assure that adverse impacts to the environment do not occur. Environmental monitoring during operations will include:

- Groundwater monitoring and analyses down gradient from all major mine facilities. A number of monitoring wells are already in place at the mine site and significant data exist about current conditions.

- Additional monitoring wells will be drilled to collect data around the mine facility including near waste rock disposal facilities and stockpiles, as well as near the tailings storage facility.

- Sampling and analysis of surface water on site when present.

- Collection of meteorological data and particulate dust information.

- Spill and leak detection systems on mine equipment.

After operations cease, environmental monitoring at the site will continue for decades to ensure no lingering effects not recognized during the operation are experienced.

Energy Efficiency

Where practical and economic, THEMAC will consider alternative construction materials and techniques to improve the overall energy efficiency of the Project. This may include renewable energy generation (solar, wind, etc.) for certain buildings.

A weather station has been in place at the mine site since 2010 and has collected, and will continue to collect, information regarding prevailing wind direction and wind speed could be applied to the analysis of the potential for wind energy generation at the site.

Reclamation

A detailed reclamation and closure plan has been prepared for the Copper Flat Mine to describe and show how the site will be reclaimed to meet performance standards and requirements of the New Mexico Mining Act, the New Mexico Copper Mine Rules, and reclamation regulations of the United States Bureau of Land Management. The plan has been presented to State and Federal Agencies for review and the plan has been determined to meet agency requirements.

The Copper Flat reclamation and closure plan will stabilize the site against erosion; return the site to the current land uses of wildlife habitat, livestock grazing and recreation; and develop a self-sustaining ecosystem. Key aspects of the plan are:

- Salvaging topsoil and growth media during construction and storing for use during reclamation

- Removing and properly disposing of operating materials, supplies and waste materials

- Removing surface facilities, building foundations and equipment

- Regrading disturbed areas for stability

- Covering disturbed areas with topsoil and growth media to support vegetation growth

- Re-seeding disturbed areas with approved vegetation species

- Providing stormwater management and erosion protection

- Performing long-term monitoring of groundwater quality and reclamation progress

Before mining activities begin, the Company will post a reclamation bond to ensure that sufficient funds are available to reclaim the site when mining is complete. Using the reclamation and closure plans described above, the Company has calculated total costs to complete the work assuming contractors are used to complete all reclamation and closure activities under the supervision of State and Federal Agencies. The cost calculation and assumptions used have been reviewed by State and Federal Agencies, and when established, the bond will be held jointly by the State and the BLM.

Brownfields Redevelopment

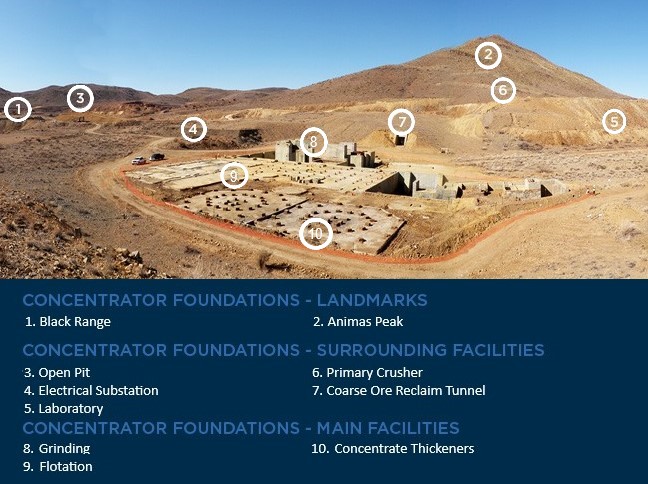

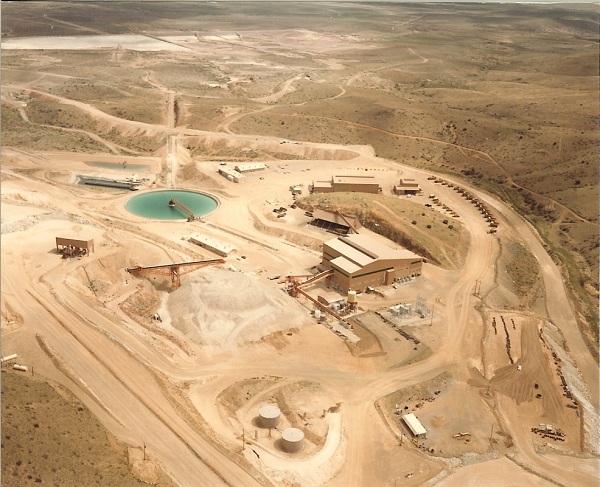

The Copper Flat Project takes advantage of significant infrastructure improvements that are a legacy from the Quintana operation in the early 1980s.

Existing Concrete Foundations

Plans for Copper Flat Mine take advantage of significant infrastructure improvements that are a legacy from the Quintana operation in the early 1980s. Incorporating existing works into the plans provide US$54M in capital savings. Existing works at Copper Flat inlude:

- 115 kV powerline from the Caballo Substation to the mine site.

- Production wellfield and 20-inch pipeline from the wellfield to the mine site.

- Diversion channel collecting stormwater from west and south of the pit and diverting unimpacted flows down Grayback Wash.

- Site grading of the process, mine shop and administration areas and access roads.

- Existing concrete foundations and structures including:

- Primary crusher structure

- Coarse ore reclaim tunnel

- Concentrator building foundation

- Metallurgical laboratory foundation

- Truck shop foundation

- Administration building foundation

- Pre-mine stripping of overburden to release ore for processing.

Existing Water Pipeline

Existing 20inch water pipeline being uncovered for testing to ensure it’s suitable for reuse

Exploration & Geology

Geology

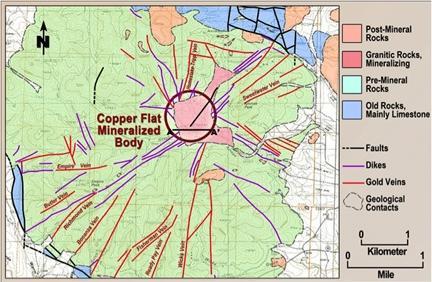

In 1905, the world’s first open pitiable, low-grade copper porphyry started production at Bingham Canyon Mine. Today, disseminated copper deposits and their associated hydrothermal systems contribute significantly towards world copper production. They account for more than 50% and over 95% of the world’s copper and molybdenum supply, respectively. Most porphyry systems also produce gold and silver as a byproduct, with ranges varying from 0.004 to 0.35 g/t Ag and 0.2 to 5 g/t Au. In 2007 the USA alone supplied up to 8% of the world’s copper demand, with the state of New Mexico ranked by the U.S. Geological Survey (USGS) as the third largest USA supplier. Copper porphyry deposits are globally restricted to two types of orogenic belts: those created along a subduction zone (where a continental and ocean plate meet) and those found along island arcs (where two oceanic plates collide). Porphyry deposits discovered along the coast of South America and North America are examples of porphyry deposits fashioned by a subduction setting. During the 1990s, through ongoing studies, the USGS concluded that approximately 350 million tons of copper had been discovered in the USA, and that about 290 million tons remained undiscovered.

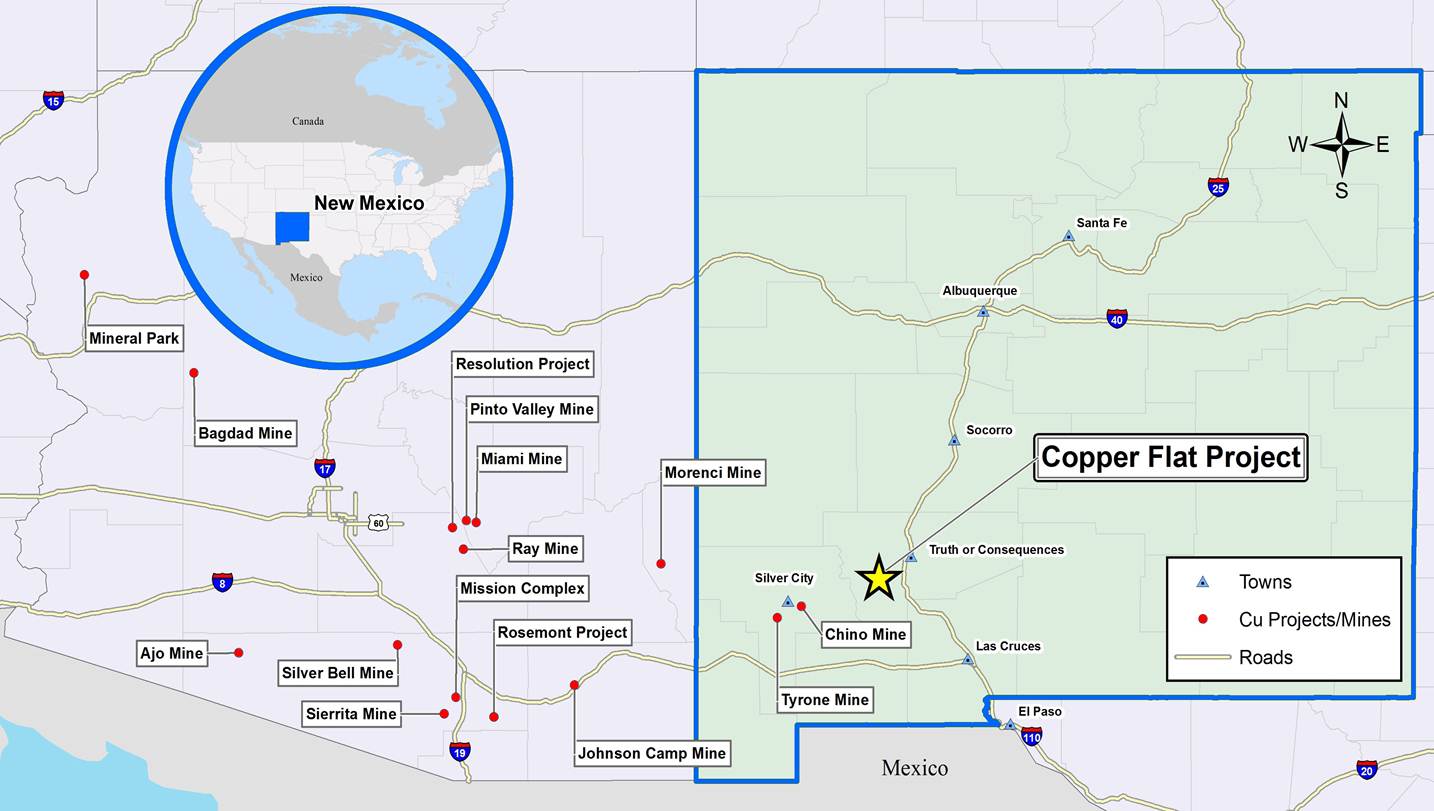

The Copper Flat Project, located in the Las Animas Mining District in South Central New Mexico, in the County of Sierra, USA, has a rich mining history stretching back to the late 19th Century. Modern exploration for porphyry copper mineralization was first initiated during the early 1950s and since, has been the primary focus within the district for many companies, including THEMAC Resources. Today, the Copper Flat Project is an advanced porphyry copper and molybdenum project. Extensive exploration has resulted in a clear understanding of mineralization distribution. The deposit is situated within a 4 mile wide stratovolcano complex with accompanying andesites and an intruded quartz-monzonite stock, known as Copper Flat Stock. Current indications suggest that Copper Flat Stock is an alkali Cu-Au mineralized breccia pipe, associated with, and genetically linked to an alkali porphyry system at depth. Breccia pipe mineralization accounts for approximately one-third of the resource. One-half of the contained copper and molybdenum is located within this mineralized structure.

Copper mineralization at Copper Flat is mostly unoxidized. It occurs in a hypogene sulfide environment largely in the form of copper-iron-sulphide or Chalcopyrite, which is hosted in the core of a breccia pipe. This style of mineralization and the associated alteration are broadly similar to other hydrothermal porphyry copper deposits in the southwest United States. Other mineralization associated with Copper Flat includes molybdenum, lead and zinc. Molybdenite (molybdenum sulphide) when present, occurs either in quartz veins, or as thin coatings in fractures. Sphalerite (zinc-iron-sulphide) and Galena (lead-sulphide) occur within the stock in minor amounts as carbonate and quartz veins associated with more dominant pyrite (iron-sulphide).

Exploration

Exploration activities at Copper Flat have developed since the 1980s. Recent exploration completed by THEMAC personnel included detailed surface mapping of all exposures within the historical pit, drainage cuts, and most of the outlying Project, covering a total area of 4,701 acres.

Extensive geochemical sampling was also completed to improve the understanding of the precious metal distribution outside of the deposit, as well as identifying other potential exploration targets.

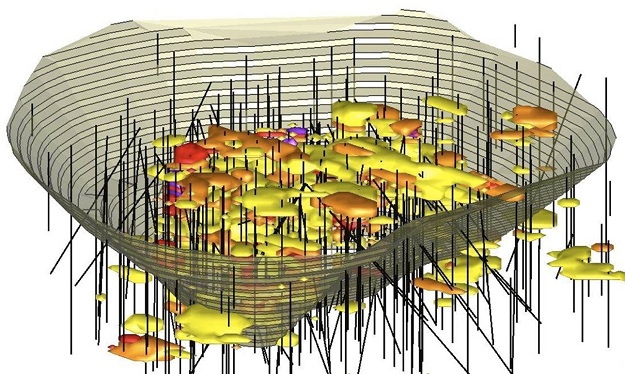

During a recent drilling program twenty core holes totaling 22,369.5’ were completed, as well as five geotechnical core holes totaling 3,609’. All core was split and assayed and the results were incorporated into the latest reserve and resource model for the Feasibility Study.

In addition to drilling and reconnaissance, the entire historical core has been re-logged to obtain lithological and structural information using core photographs. Additional mineralogical and metallurgical studies have been undertaken and geotechnical studies have been completed. A CSAMT geophysical survey was completed in the central part of the project to investigate and define the extent of the CFQM and sulfide mineralization.

Following completion of the 2012 drilling program, the footprint of the Copper Flat deposit is now considered fully defined for the purpose of the Feasibility Study. There is potential to futher expand the known copper reserve and resource base through additional drilling. Any drilling undertaken will be focused on attempting to extend the deposit at depth (below the bottom of the planned pit). The margins of the deposit and in particular the northeastern lobe of the deposit will also be drill tested.

3-D Grade Model

Technical Reports

Location & History

LOCATED IN ONE OF THE WORLD’S MOST PROLIFIC COPPER MINING DISTRICTS

The southwestern states of the USA are host to some of the world’s largest and most prolific porphyry copper deposits. Typically the ores are moderate, but their exceptional scale result in them being the most economical to develop. The Copper Flat Project is located in the historic Hillsboro mining district of New Mexico, USA. Following the discovery of placer gold and silver deposits in the late 1870’s, it was one of the first districts to be mined. For a century, silver and gold was produced from placer operations in the vicinity of the Copper Flat Project.

History

The first copper smelter was developed in the town of Hillsboro in 1892 and operated until the early 1900s. Small-scale copper and precious metal mining continued in the district until 1941. Between the 1950-1960s majors such as Newmont Mining Company (Newmont) and Bear Creek Mining Company (Kennecott’s former exploration subsidiary) became involved in the district, and had varying exploration exposure to the project area.

In the past 30 years there have been two significant efforts to bring the Copper Flat mine into production. The first effort was by Quintana Minerals who successfully achieved production in 1982 following a $112M capital investment. With a capacity of 15,000 st/d and a waste ore ratio of 1.8:1 the mine ran in full production for three and a half months. Financed on a $1.70 /lb copper prices the company was unable to sustain the low copper prices of $0.70/lb. Coupled with this were the high interest rates on the CIBC (Canadian Imperial Banking Corporation) loan. The mine was put on care and maintenance in the expectation that it would be reopened once there was an economic rise in copper prices. Eventually the mine was dismantled prior to a copper recovery and the concrete foundations were covered.

The initial mining in 1982 proved that there are no adverse processing factors or harmful by products which would require additional engineering and environmental control. With a change in copper prices, modern extraction techniques, and successful management, it is evident that there is significant production potential at Copper Flat.

The second effort was with Alta Gold which acquired the property in 1994. Having obtained a draft final EIS for the project in 1999, the company went bankrupt (following financial difficulties with other assets) just prior to the final issue of permits.

Alta’s exploration, engineering and environmental studies contributed significantly towards the development of the Project. Resource and environmental data was progressed to standards consistent with current regulations. The work carried out in the 1990s further underpins the economic and operational viability of the Copper Flat Project.

Landing Page

The Importance of Copper

Society’s need for minerals is experiencing a dramatic shift. In a single generation, we have experienced a tremendous increase in the uses and demand for a growing list of critical and strategic materials that are needed to address issues such as climate change. Copper is one of those materials.

Copper is a critical component of the clean energy revolution and uses for copper are rapidly expanding with the energy transition that is occurring today. Copper has superior properties that allow it to be used for many types of clean energy, including cost and electrical conductivity. Copper is used in a growing number of applications that range from power generation to energy storage and in the shift to electric and hybrid electric vehicles.

The Copper Development Association predicts that by 2040, wind and solar will produce more electricity than any other source in the world. As these technologies grow, they will depend heavily on copper’s reliability and high standard of performance to generate, transmit and store electricity. Current statistics for the use of copper include:

- Electric vehicles now contain three to four times the amount of copper used in a conventional fossil fuel only powered vehicle

- There are 7,800 pounds of copper per megawatt of power output in a typical land-based wind farm power system

- 11,000 pounds of copper per megawatt of solar power systems

Project Status

Permitting Federal EIS and ACOE 404 Complete

State AQ and DP Complete

State Mining Permit at Advanced Stage

Reserves & Resources

Mineral Reserves

| Cut-Off Grade (NSR/t) | Tons (000s) | Cu Eq (%) | Copper (%) | Moly (%) | Gold (g/t) | Silver (g/t) | |

|---|---|---|---|---|---|---|---|

| Proven | $6.11 | 78,857 | 0.32 | 0.010 | 0.096 | 2.25 | |

| Probable | $6.11 | 34,227 | 0.25 | 0.007 | 0.096 | 1.29 | |

| Total | $6.11 | 113,084 | 0.39 | 0.30 | 0.009 | 0.096 | 1.93 |

Mineral Resources (Includes Mineral Reserves)

| Cut-Off Grade (NSR/t) | Tons (000s) | Copper (%) | Moly (%) | Gold (g/t) | Silver (g/t) | ||

|---|---|---|---|---|---|---|---|

| Measured | $6.11 | 126,655 | 0.28 | 0.009 | 0.096 | 1.93 | |

| Indicated | $6.11 | 178,571 | 0.19 | 0.005 | 0.064 | 1.29 | |

| Total | $6.11 | 305,226 | 0.23 | 0.007 | 0.078 | 1.55 |

(1) Effective October 7, 2013

(2) Mineral reserves and resources based on $3.00/lb Copper, $8.00/lb Moly, $1,350/oz Gold and $20.00/oz Silver

(3) Mine design based on $2.25/lb cone pit

Low Cost of

Production

Copper Flat is well positioned in the 2nd Quartile of the Global Copper Cost Curve.

Total production costs are estimated at US $1.20 per pound of copper produced during the first five years of production and US $1.45 per pound of copper produced for the life of mine.

Low Capital Intensity

The initial capital cost is estimated to be US $374M, which is $10,650 per ton of annual output capacity.

Brownfield Redevelopment

The Project is a Brownfield Redevelopment Project in a stable region with excellent access to existing infrastructure. The Project will realize savings through the reuse of significant infrastructure that remains from the original Quintana Mine, which provides an estimated $53.9M in value to the Project.

Financial Return

| Copper Price($/lb) | NPV($M) | IRR(%) | Payback(Yrs) |

|---|---|---|---|

| $3.00 | 165.0 | 17.3% | 3.7 |

| $3.25 | 240.4 | 21.1% | 3.3 |

| $3.50 | 314.1 | 24.5% | 3.0 |

| $3.75 | 387.5 | 27.8% | 2.7 |

(1) Base case price assumptions based on $3.25/lb Copper, $10.50/lb Moly, $1,300/oz Gold, $16/oz Silver; post private royalty of 3.25%

(2) After Tax NPV at 8% Real Discount Rate

Mining Metrics Table

| Mine Operating Life (Years) | 11.1 |

| Average Annual Ore Process Rate (Million Short Tons) | 10.2 |

| Mill Head Grade (% Cu) | 0.298% |

| Mill Head Grade (% Cu Eq) | 0.378% |

| Mine Strip Ratio (Waste:Ore) | 0.40 |

| Copper Recovered (LOM Average Annual Tons) | 28,000 |

| Gold Recovered (LOM Troy Ounces) | 227,000 |

Form 43-101F1 Technical Report Copper Flat Feasibility Study Update, April 2020

Form 43-101F1 Technical Report Copper Flat Feasibility Study Update, April 2020